PEX Problems

Cross-linked Polyethylene (PEX) has been used since the 80’s. Originally used in Europe, it is now very popular in the United States. Home inspectors often see PEX improperly installed. We know that PEX manufacturers normally want installers to use a manifold system with “home runs” to the individual fixtures. Multiple elbows and “T” connections are not ordinarily recommended. A past newsletter specifically details PEX installation procedures. You can find a great PEX installation manual by CLICKING HERE.

Recently there have been at least two lawsuits pertaining to PEX installation. There was also a recent case where Uponor reached a $18 Million class action settlement. This settlement deals with fitting issues. More information can be found on the “News from the Home Inspector World” & “New Products” links in the right pane of this newsletter.

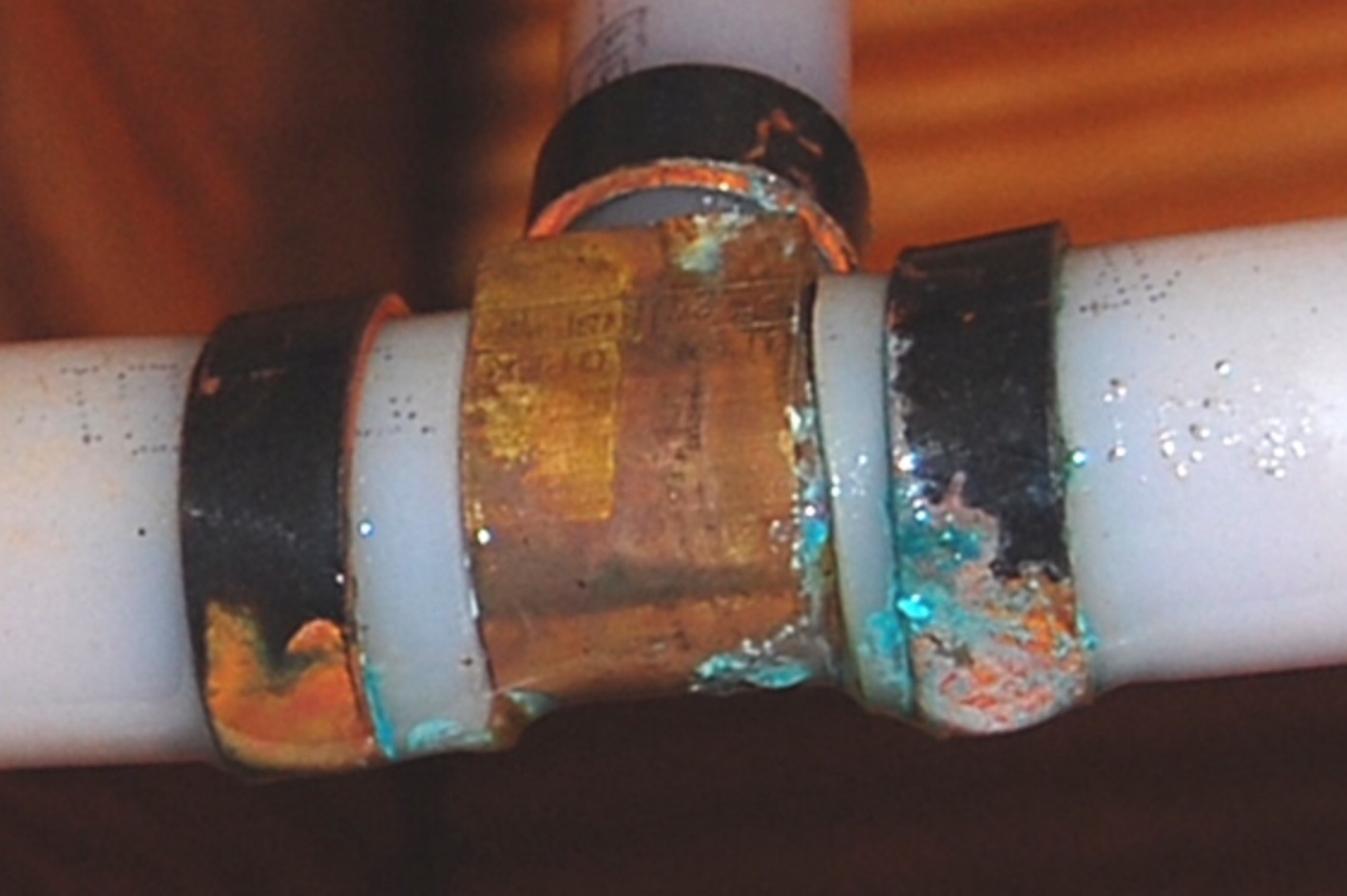

So what are some of the alleged problems associated with PEX installation? Some brass fittings may fail due to dezincification. This may occur when zinc leaches from the fittings. It will create a white powder substance from the breakdown and possibly reduced water flow. It may also cause leaks in the fitting (see photos above).

High levels of chlorine have been known to oxidize the inner wall of some types of pipe causing the connections to fail. We saw this problem with Polybutylene pipe. Some manufactures have added antioxidants to the pipe for sacrificial purposes. The chlorine will degrade the antioxidants before the pipe. It is not known the long term effect of chlorine and pipe failure. The amount of chlorine used in Europe is significantly lower than the U.S. A higher level of chlorine may cause accelerated degradation.

Some types of plastic pipe are manufactured in a manner where chemical leaching may occur. This involves leaving chemical byproducts behind in the pipe. Buried pipe may also be permeable when exposed to some solutions including oxygen, petroleum products, and chemicals. This may cause toxic chemicals to leach from the pipe material.

Many PEX manufactures have addressed potential issues and have also introduced different grades of PEX for specific uses. For instance:

- Non-Oxygen Barrier PEX for potable water

- Oxygen Barrier PEX for heating system components that may rust or corrode

- PEX – A – flexible, less kink resistant, & freeze resistant

- PEX – B – slightly less flexible and not as freeze resistant as PEX-A

- PEX-AL-PEX or Aluminum Barrier PEX – impregnated with a layer of aluminum, it keeps it shape when bent. The aluminum also is an oxygen barrier and has a low expansion rate. This is used for outdoor or high temperature heating systems.

What should a home inspector be looking for (especially in older PEX):

- Proper installation (refer to past newsletter or the PEX installation manual)

- White powder around PEX fittings (see photos at the beginning of article)

- Visible leaks or “weeping” especially at the fittings

- Reduced water flow at the fixtures

- PEX should not be exposed to sunlight, even through windows

- PEX should be protected from potential nail or screw pierce

- Odor or bad taste of the water

It is currently uncertain how any of these potential conditions may effect plumbing pipe manufacturing and it’s expected serviceable life. Of course, improper installation will also cause failure. Reviewing the installation manual will help you understand what to look for when inspecting PEX pipe.

Related Articles

- Inspecting Hot Water Circulation Systems

- Inspecting Heat Pump Water Heaters

- Plumbing Saddle Drain Fittings

- Hot Water Tank Requirements After April 2015

Want To Learn More? Click HERE to Search Our Full Database Of Home Inspector Newsletters.