Inspecting Fiber Cement Siding

When people hear this term they immediately associate it with Asbestos cement shingles. Many homes were sided with them years ago. Concrete or cement fiber shingles are still available; however Asbestos is no longer used. New cement fiber siding consist of Portland cement, sand, and cellulose (wood) fibers. There has been a wave of new cement fiber siding products over the last several years. Whether you liked older Asbestos cement shingles or not, there is no denying that they are very hardy (although brittle). I inform my clients that older cement fiber shingles are durable, and can easily be painted. They wear very well and will last a long time with very little maintenance. Because the Asbestos fibers are contained in the shingle, they do not pose a significant risk, unless they are drilled, cut or sanded.

We are now seeing issues and even lawsuits regarding new fiber cement siding (click News from the Home Inspector World in the left pane for more information on one lawsuit). You can see in the pictures above some issues associated with cement siding.

The pictures at the top of this article will give you an understanding of how cement siding should be installed. So what are some of the things a home inspector should be looking for and how should you properly advise your client when inspecting cement fiber siding.

- Cement fiber siding should not be installed wet or if it has been saturated. Doing so will cause it to shrink after being nailed in place causing gaps

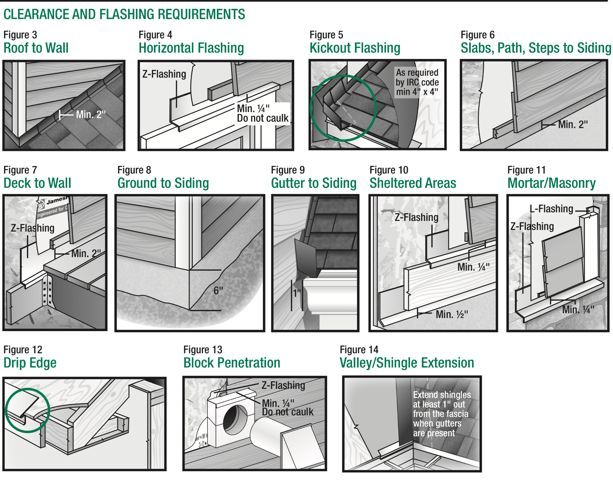

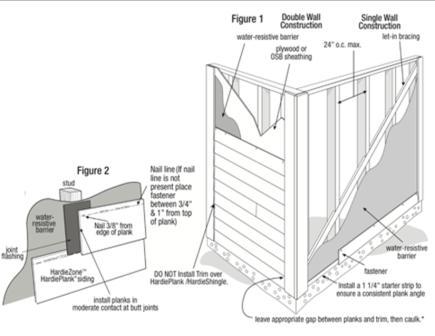

- A properly installed weather resistive barrier must be installed under siding

- Cement fiber siding should be kept a minimum of 6 inches above grade

- Cement fiber should not be used for fascia or trim pieces

- Joint flashing should be used behind the siding at joints and seams

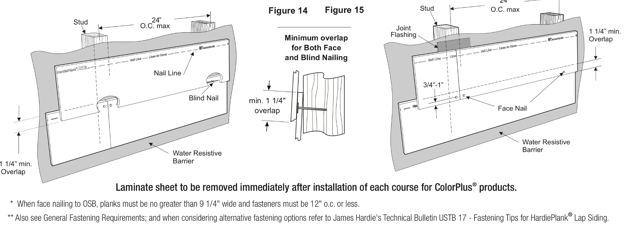

- It should be nailed between ¾” and 1” below top edge of siding

- The maximum distance lap siding should be installed over studs is 24” OC or directly to a minimum 7/16” thick wood substrate

- Trim should not be installed over the siding. Instead there should be an appropriate gap and caulk should be used

- There should be a 1 ¼” starter strip installed

- Appropriate corrosion resistant, galvanized, or stainless steel nails and fasteners should be used

- Aluminum fasteners, staples, or clipped head nails should not be used

- Fasteners should be perpendicular and snug to the siding, no air gaps and not countersunk

- Cement fiber siding will warp due to improper nailing

- Flaking of the surface can be due to water exposure or manufacture issues

- Cement fiber siding will also crack if struck

- Flashing should be installed as necessary, similar to any siding material especially top cap flashing

Related Articles

- EIFS – Additional Inspection Guidelines

- Deck / Porch Flashing

- Inspecting Balconies

- Forgotten Flashing