Inspecting Through The Wall Thimbles & Flue Pipes

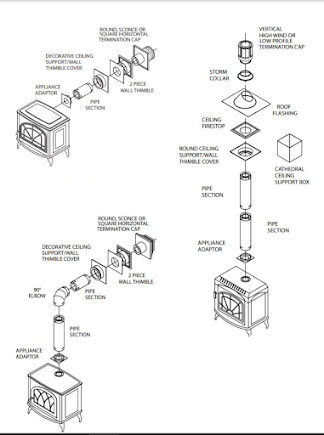

I think every home inspector has seen a flue pipe from a wood stove or a gas unit penetrating a wall or ceiling and think; “that does not look safe.” Whether it is the pipe itself or clearances, I have outlined some guidelines that may assist you in the field. Although there are many codes and accepted standards this is a good rule of thumb. Through the wall thimbles should be used for all applications unless not required by the manufacture. Horizontal runs of vent pipe must be supported to prevent any downward sagging. If the wall being penetrated is constructed of noncombustible material only, i.e. masonry block, brick, or concrete only, a hole with zero clearance to the vent pipe is permissible if allowed by the appliance manufacturer. See the graphic for through the wall thimble locations. The vent should not run downward. A downward slope can trap heat and become a possible fire hazard. Listed below are some recommended clearances by one manufacture:

- Clearance above the ground, veranda, porch, deck, or balcony is 12 inches minimum or over the snow line.

- Clearance to a window (operable or fixed closed) or door is 12 inches minimum.

- Vertical clearance to a ventilated soffit located above the termination cap (if soffit extends a horizontal distance of 2 feet out over the centerline of the termination) is 18 inches minimum.

- Clearance to an unventilated soffit is12 inches minimum.

- The flue should not be installed above a gas meter/ regulator assembly within 3 feet horizontally from the centerline of the regulator.

- Clearance to a service regulator vent outlet is 6 feet minimum.

- Clearance to non-mechanical air supply inlet to a building or the combustion air inlet to any other appliance is 12 inches minimum.

- Clearance to a mechanical air supply inlet is 6 feet minimum.

- Clearance under a veranda, porch, deck or balcony: 12 inches minimum.

In addition to the recommended clearances a home inspector should be looking for the following conditions:

- Fire stops are required at each floor / ceiling level.

- Twist lock connections do not require screws are not required to secure the joint, but are acceptable provided they do not penetrate the inner wall of the vent pipe.

- Horizontal pipe sections should be supported at least every 4 feet.

- Most vents do not require sealant, unless specifically required by manufacturer.

- The horizontal run of venting must be level, or have a 1/4-inch rise for every 1-foot of run towards the termination.

- The arrow on the vent cap should be pointing up

- The Vinyl Siding Standoff prevents excessive heat from potentially warping or melting the vinyl siding material and is required

- If a vent passes through any occupied areas above the first floor, including closets and storage spaces, it must be enclosed. The enclosure may be framed and dry walled / plastered with standard construction materials, but required clearances to combustibles must be maintained.

- Air spaces should not be filled with insulation.

- If a vent passes through an attic space, an attic insulation shield, or a chase enclosure, it must be installed to prevent contact between flue sections and the insulation or other debris.

- For vaulted ceilings a chase enclosure must be constructed for the flue to pass through

- The through the wall thimble should be centered through a square framed opening in wall / ceiling

Related Articles:

- Inspecting Heating and Cooling Ducts

- Masonry Fireplace Inspection

- Looking For Back Draft

- Direct Vent Gas Fireplace Clearances

Want To Learn More? Click HERE to Search Our Full Database Of Home Inspector Newsletters.